CURRENTLY, cement-manufacturing is one of the important areas that has been significantly stymied due to high electricity costs, but this could soon change with the establishment of Guyana’s landmark US$900-million gas-to-energy project which is earmarked for a 2024 start-up at the Wales Development Zone in Region Three (Essequibo Islands-West Demerara).

This is according to a comprehensive Waste Management Plan crafted by ExxonMobil and its partners, outlining how it intends to tackle waste management in its oil-exploration and production operations.

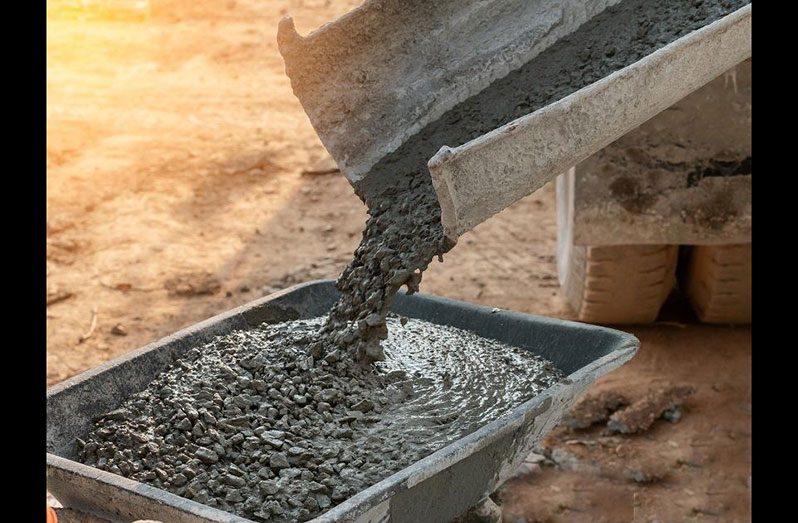

The “cradle-to-the-grave” study outlines the fact that despite growing needs for materials to facilitate Guyana’s construction boom, local cement-manufacturing is not feasible. The document also highlighted the fact that while some investors have attempted to manufacture the material in the past, almost all of them have had to shut their doors, even as the country continues to import the product in bulk.

“Historically, a cement-manufacturing operation was started up in December 2014 but ceased operations in October 2017. As recently as January 2019 a new concrete-mixing plant was commissioned by TCL Guyana/CEMEX, but this new plant relies on imported cement manufactured abroad,” the report indicated.

Admittedly, the previous A Partnership for National Unity +Alliance For Change (APNU+AFC) had called for local and foreign investors to examine the possibility to starting up cement-manufacturing operations here; however, little to no efforts were made to create conditions where such ventures would or could become feasible.

Fast forward to 2022, the energy mix being embarked on by the People’s Progressive Party/Civic (PPP/C) government signals a major turnaround in the construction industry.

“…the proposed gas-to-power project offers up the potential to change [the] cement-manufacturing economics in Guyana,” the report outlined.

It was noted that currently, in addition to high energy costs, one of the largest barriers to the establishment of cement-manufacturing outlets in Guyana is the lack of primary raw materials, more specifically, limestone.

“There are no extensive limestone deposits located in northern Guyana, so all bulk limestone materials would have to be imported from the Caribbean Region,” the study explained.

But even with the lack of sufficient limestone here, the report indicated that “It is possible that low-cost energy resulting from the proposed gas-to-power project could offset the high costs of importing raw materials from the distant Caribbean Region.”

This could make the prospect of cement-manufacturing in Guyana more feasible.

“However, the overall feasibility of such an endeavour would require a detailed economic analysis as well as the interest of a multi-national cement manufacturer,” the oil conglomerate said.

It noted too that outside of low energy costs, the ongoing oil operations also lends to the emergence of a thriving cement-manufacturing industry, should systems be put in place to utilise alternative fuel and raw materials (AFR) emanating from local petroleum production.

The AFR programmes, according to the study, uses waste materials, including used tyres, used oil, oily waste-waters, organic chemical wastes, and other wastes with calorific or elemental value into the cement-production process.

The oil-and-gas development and production wastes best suited for treatment in cement co-processing include alternative raw materials such as all drill cuttings and alternative fuels, such as oily sludges, oily rags, contaminated packaging, and other hydrocarbon wastes.

According to the study, waste co-processing and the use of AFR are intended to be substituted for the use of traditional kiln fuels such as coal or diesel fuel, as well as certain raw materials such as (shale, clay, etc in the cement-manufacturing process, “which uses high-temperature kilns to produce the cement clinker product.

“The primary benefits of the use of cement co-processing for treatment of these wastes are: reliable and effective treatment of hydrocarbon-based hazardous wastes; the elimination of all landfill disposal of residual wastes; more consistent treatment of waste,” the study indicated.

It also advised that planning for any and all future cement-manufacturing operations in Guyana should consider provisions for waste co-processing and the use of AFR.

Some examples of the ‘other’ types of fuels used by plants are engineered fuels, refuse-derived fuels, agriwaste, biomass, carpet, plastics, rice hulls, sawdust, textile waste, and wood. Alternative fuels are also currently being used in cement plants in Brazil, Chile, Ecuador, Colombia, and Argentina.

Nonetheless, with preparatory works on the gas-to-energy project slated to come on stream soon, and with the construction industry pegged for a 10.5 per cent growth, Guyana has already begun to field interests in local cement-manufacturing.

It was only last year that a Guyanese-owned company named Vas Energy Incorporated kickstarted a venture to establish a US$100M state-of-the-art cement plant at La Resource, Essequibo Coast, in Region Two (Pomeroon-Supenaam).

The project plant will have the capacity to manufacture hydraulic cement, suitable for sea defence projects for not only the entire country, but neighbouring countries as well. Previous reports have indicated that the new cement plant would essentially reduce the cost of imported cement by 30 per cent.

.png)