–aims to restore confidence in local market

AS he watched his cattle graze for several hours in the backlands of Lightown Village, East Bank Berbice, in 1982, Mitford Ward recognised that the time spent restricted the amount of work he could have done to gain an income . Subsequently, he resorted to farming, producing corn and plantain, thereafter adding value to the raw agricultural material through product transformation:- postharvest grading, sorting, washing, packaging, storage and distribution.

“Back then, the economy was not doing too well. I had worked at Transport and Harbours Department, but left. Salaries could not afford you a reasonable standard of living, so I resorted to farming. Watching the cows robbed me of working time and income. I thought of something I can do in the evening. I thought of milling, as the term ‘agro processing’ was not known back then”.

Ward, fondly referred to as ‘Wardy’, started on a small scale, milling corn and plantain flour, and, with support from other farmers , the businesses thrived, moreso, during the PL480 arrangements, when Guyanese had to revert to local flours, due to restriction on the wheat products.

After the death of Guyana’s first Executive President, Forbes Burnham, in 1985, President Desmond Hoyte, on ascending to office, lifted the restriction on wheatened flour. As a result, the local market almost came to a halt.

However, prior to the decline in business back then, Ward saw the need of having his first mill, after viewing one in the showroom of the once popular Guyana Stores.

“I visited the store, just to observe the mill. It was expensive. I just could not afford it. I decided to have it fabricated. I sketched the mill at the now defunct ‘ Barry’ workshop. The fabricator named Thomo looked at the sketch and said, “if it don’t work, don’t blame me” …. After its completion, my mother’s land tiller gasolene engine was added . Several trial runs lead to the successful milling of the agricultural products…. The business got bigger than anticipated. Back then persons would travel by Tata buses, from across the country bringing with them bags of corn which I would mill, thereby supplementing my income.”.

It was after wheatened flour was allowed back into our country in 1985, that the business got slow. As a result, Ward moved his mill from Lightown, East Bank Berbice, to the now defunct Bristol’s bakery at Pitt Street, in New Amsterdam. At the new location, he continued the processing on a smaller scale until 1993. For the next nine years, he shifted his means of income, and became a hire car driver, even while attending classes at the University of Guyana. In 2013, after working with the Probation and Social Services, Warde retired as a Probation Officer.

However, his retirement was not for relaxation, as he returned to agro processing, with a wider knowledge, exposure and ideas.

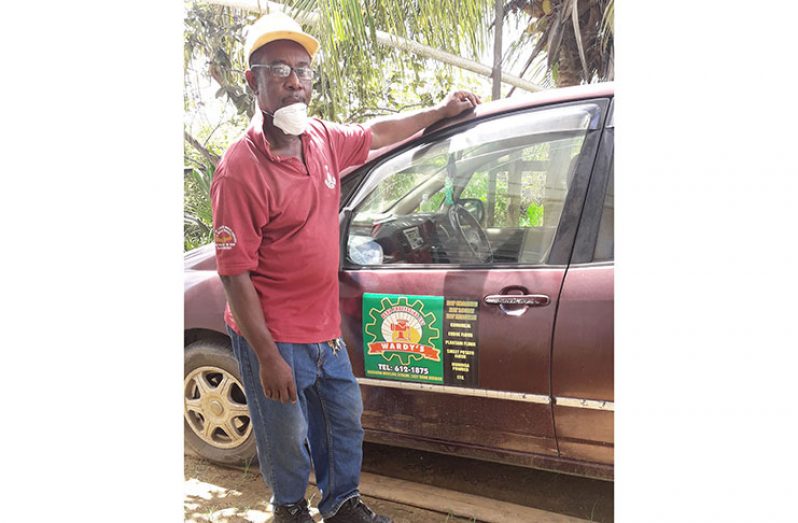

“I am at my own home now at Lot 1354 Glasgow Housing Scheme, Greater New Amsterdam, and I am able to produce a variety of flours, inclusive of barley, split peas, channa, eddo, cassava, rice, sweet potato and moringa powder. I have dryers. I have set up the business according to Food and Drug requirements.’

But, although the business has its gains, like any venture, there are challenges, especially when drying products during a rainy season. However, with a subsequent implemented method, products can now be dried within two to three days.

“As an agro processor, having equipment such as dryers at a reasonable cost will assist in boosting one’s business. We need duty free, loans and grants to be more accessible to all.”

“Another challenge is labelling and packaging . Plastic factories are not catering for small businesses. The minimum printing is 30,000. There must be a plate (mould) for each product which is bordered overseas. …The final cost catapults into millions. …The small man has to revert to paper.'”

Other challenges include the accessibility of raw materials. In Guyana, the supply fluctuates. When there is a glut, the cost is cheap, but, when it’s scarce, its expensive. There is a stiff competition with the cornmeal coming from Barbados and Canada, and their prices are consistent because of storage facilities.

“Brazil is a leading producer of corn . It’s cheaper, less than half the price our farmers are asking, but, our cornmeal is richer, as farmers often-times would plant on virgin lands, void of fertilizers.

For us in Guyana, there is a storage problem. If corn is not stored properly, it becomes infested with weevil. It will not taste good nor would it be hygienic. “However, I have overcome that challenge, by storing in plastic barrels and sealing with sponge. Also, I have a 450 gallon silo bin for storage.

Prior to storage, the various products which are bought from farmers countrywide, are washed and heated in an oven so as to kill any organisms or eggs, as infestations can affect quality of product”

“My desire is to provide wholesome food, as I recognise that the segment of the population which uses most of these products are children and babies whose immune system is now developing. So, I focus on the products being prepared in a hygienic manner.”

That aside, Mr Ward envisage a future of expansion, where high protrin porridge mix, along with Dandelion teas, among others, will be added to his wide range of products which can be found in local supernarkets around Demerara, inclusive of Linden, and the Guyana Shop at Robb and Alexander Streets, Georgetown.