LEADERSHIP

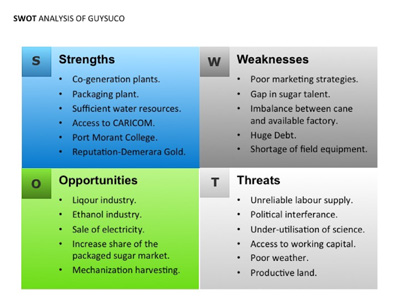

WE cannot lead unless we have our fingers on the pulse of the issues. The broad issues at GuySuCo are outlined below in a SWOT analysis. I will expand on this SWOT analysis in this week’s column and in next week’s column.

But before we dig deeper into this SWOT analysis, let us address some key issues on leadership. In light of all the above knowledge, if we do not have the competency to inspire and resolve conflict and effectively communicate our vision, we are actually flying at half capacity. Here are some tough questions: Do we think the ordinary cane-cutters are inspired and proud of GuySuCo as their place of employment? Does their current leadership team motivate them?

But before we dig deeper into this SWOT analysis, let us address some key issues on leadership. In light of all the above knowledge, if we do not have the competency to inspire and resolve conflict and effectively communicate our vision, we are actually flying at half capacity. Here are some tough questions: Do we think the ordinary cane-cutters are inspired and proud of GuySuCo as their place of employment? Does their current leadership team motivate them?

Please note I did not use the word “like,” I used “inspired” and “motivated,” since even if the leadership is likable, that does not make them inspirational to motivate the team.

Inspirational leaders are mentors who have the character to motivate the entire team, from the cane-cutters up to the top leadership. Leadership skills can be found in anyone, and some of the best leaders are the factory and field foremen. What we have at GuySuCo is that “dotish” mentality that is based on “command and control,” which says I am the boss and I know best; trust me. Hell NO!

The new way is to inspire, influence and motivate the workers to be the best they can be; and in the process, get them to the point where they see the industry as their own, and thus continue to contribute beyond the call of duty to turn the industry around.

The overall leadership in GuySuCo today cannot inspire the workers, because, for years, they have not effectively managed resources for the betterment of the industry, and the workers know this as fact. If one were to observe how Raj Singh managed that industry, one would see that he was one of the most despised officials. The difficult job now is to retrain the leadership to unlearn the command-and-control dictum, and learn now to influence all levels to work beyond the call of duty.

One thing that the workers will always hold against the Raj Singh team was how that team failed to justify their decisions to the key stakeholders, such as the workers’ unions (GAWU, NAACIE). How can you make a G$44-billion decision, such as constructing a sugar factory, and not seek the buy-in from the workers’ representatives? The workers are aware that there was a cheaper bid from a more experienced Indian company, but the leadership chose a more expensive bid from a novice Chinese builder, who had previously never built a sugar factory in its life. Do you think the workers will ever trust such leadership?

TIME MANAGEMENT

The workers also know that time-management is sorely lacking in the industry. In the sugar industry, time is gold. The real money is situated between the time the cane is chopped and the time it is crushed and transformed into sugar. Any delay in that process will hit the industry for billions, as the sucrose content is rapidly depleted if this process is not managed with precision.

Do we have a system that tests the sucrose content in each field, and tag accordingly, so that a “cane-chopping plan” can be pursued to ensure that the sugar cane is cut, crushed and processed at the optimal moment to extract the optimal sugar from the plant? Everything has to be driven by when the cane is ready, not when the manager says let us grind. But if the cane is ready and the factory is not, then there will be delays, and every day of delay means losses. This is an extremely tricky situation, and this is the most powerful argument to ensure that central government urgently finances an accelerated programme to incrementally mechanise the fields on all estates in spite of the challenges.

LEADERSHIP IN THE SCIENCES

What about the scientific husbandry practice? Are we aware of the soil deficiency per field in each estate as close as possible to real time? Are we aware of the respective disease or weed issues per field on each estate as close as possible to real time? Are we collaborating with UG to provide science students to add manpower to this process? Have we properly mapped out and tagged the entire acreage?

With such information, we can really drive cost down as we optimise the use of fertilisers and agro-chemicals.

Dr. Evans, from the Booker’s days, had developed a technique called the “foliar diagnostic technique,” which basically permitted the examination of samples of cane leaves using rangers and the laboratory to detect the health of samples of cane plants on each respective field. His focus was nitrogen, potash, and phosphate deficiency. This process allowed corrective measures to be taken within 10 days by applying the right amount of the relevant fertiliser dressing to re-energise those fields at the respective locations.

This kind of rolling information is vital to ensure that we do not waste two of the most expensive inputs into the industry — fertilisers and agro-chemicals. Controlled use of these products is so important in saving billions of dollars, yet I am advised that GuySuCo is not practising this art in a structured manner. What is really wrong with the leadership at GuySuCo?

FLOOD FALLOWING

All the sugar experts around the world know that, after working a field for 5-6 years, even with fertiliser application, the yield will drop because of soil exhaustion. This is not rocket science; it is common- sense. Flood fallowing is a process whereby the land is rested under nine inches of water for six months. The water is then drained away and new ratoons are replanted. Unfortunately, GuySuCo can be accused of extending this important process to periods as long as 12 years in many cases, which has institutionalised poor yields.

This is absolute insanity, since, across the world, flood-fallowing has proven to increase yield between 30-40 percent, and thus it makes absolute financial sense to carry out this important process at the prescribed time of between 5 and 6 years.

In the days of Bookers, they had a standard model, wherein 15 percent of the fields were flood-fallowed and replanted every year. Do we understand why in many of the Bookers’ years, using archaic technology, they saw a production of over 300,000 tonnes of sugar and had a better yield rate that GuySuCo in 2014? They got the science right then! Today, with superior scientific knowledge, we continue to get the scientific techniques wrong.

We shall continue next week on why leadership has to change in GuySuCo and on this SWOT analysis.

.png)